The field of biopharmaceuticals, as a rapidly expanding branch of the pharmaceutical industry, is having a profound impact on healthcare. With numerous biopharmaceuticals being approved and entering the market, the research and development as well as production processes of biopharmaceuticals have become increasingly complex. CMC (Chemistry, Manufacturing and Control) plays a crucial role in the field of biopharmaceuticals, ensuring a smooth transition of biopharmaceuticals from the laboratory to the commercialization stage. CMC covers the entire process of biopharmaceuticals, from raw material selection, process development, production scale expansion, quality control to the final market launch of the drugs. Mastering the basic knowledge of CMC, its practical application in biopharmaceuticals, and its future development trends is of vital importance for promoting the advancement of this field.

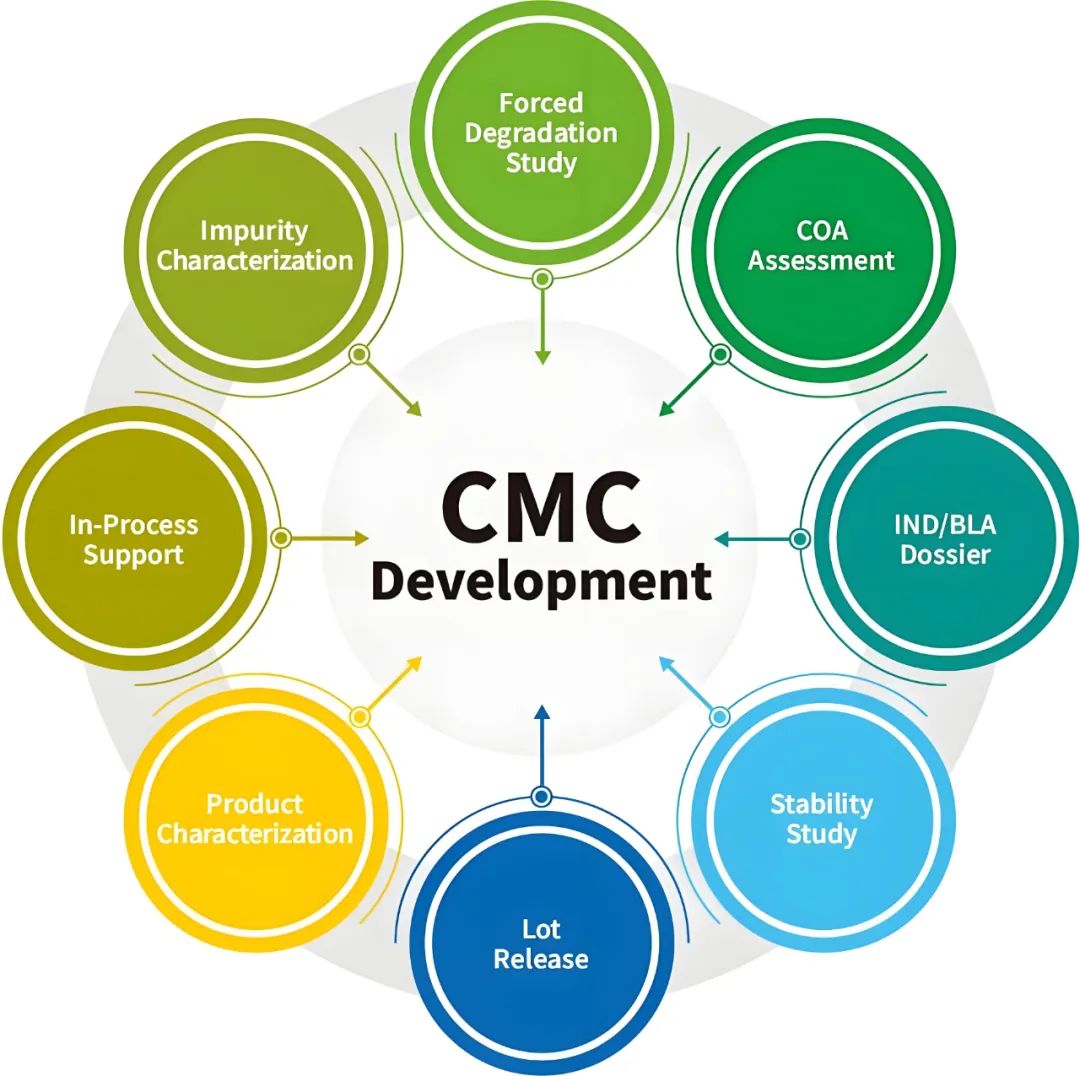

CMC is a series of scientific and technological activities aimed at ensuring the safety, efficacy and quality of drugs during the research and development and production processes. In the field of biopharmaceuticals, CMC mainly involves the following aspects:

①chemistry: This section mainly studies the molecular structure, chemical stability, impurity analysis and degradation pathways of products. For biopharmaceuticals, the chemical part focuses more on the structural identification and characteristic analysis of biological macromolecules such as proteins, antibodies, and nucleic acids.

②Manufacturing: This is the core of CMC's work, encompassing process development, production optimization, process scale-up, and production consistency. The production of biological drugs involves complex steps such as cell culture, purification, concentration and formulation. Therefore, the challenge in the manufacturing part lies in how to ensure the stability and consistency of large-scale production.

③Control: This part involves the monitoring and control of drug quality, mainly through physical, chemical and biological testing methods to ensure the purity, potency and safety of the product. Due to the complexity of biopharmaceuticals, their quality control processes are more stringent, especially for antibody drugs or vaccines. CMC must include multiple tests such as titer testing and microbial contamination monitoring.

The key role of CMC in biopharmaceuticals:

①The bridge from research and development to production: CMC runs through the entire life cycle of drug development and is an important link connecting drug research and development with large-scale production. In the early stage of drug research and development, scientists usually use small-scale production to obtain preliminary data. However, after entering the clinical trial stage, the production scale and process must be rapidly adjusted to meet the demands of larger volumes. The task of the CMC team is to optimize the production process and ensure that the drugs produced each time have consistent quality and potency.

②Ensuring product quality and safety: Unlike traditional chemical drugs, biological drugs have extremely complex molecular structures, and thus their quality control is also more complicated. CMC is responsible for formulating and implementing strict quality control measures to ensure that products meet regulatory requirements at all stages of production. These control measures include purity testing of products, analysis of degradation products, and determination of antibody titers, etc.

③Support for drug clinical trials: Before a drug enters clinical trials, it must undergo a detailed CMC assessment. The CMC team needs to provide detailed data on production processes, quality control methods and product stability to regulatory authorities to ensure the safety and efficacy of drugs in clinical trials. For biopharmaceuticals, the CMC team also needs to consider the immunogenicity and stability of the biological products, as these factors directly affect the efficacy and safety of the drugs.

④Compliance and regulatory support: The regulatory environment for biopharmaceuticals is extremely strict. Regulatory authorities in various countries (such as the FDA and EMA) have put forward detailed requirements for the CMC part of biopharmaceuticals. The CMC document needs to describe in detail the production process of the drug, the chemical properties of the product, the impurities that may be generated during the manufacturing process, and the quality control methods. Compliant CMC documents not only facilitate the approval and marketing of drugs but also lay the foundation for the market sales and internationalization of the products.

In the field of biopharmaceuticals, the core process of CMC runs through the entire drug development cycle, specifically including the following key steps:

①Process development: As the cornerstone of CMC, process development determines the production methods and quality control strategies of drugs. In biopharmaceuticals, this includes the development of cell lines, the optimization of fermentation processes, and the establishment of protein purification procedures. The goal of process development is to ensure the continuous production of high-quality drugs while maintaining production efficiency.

②Quality control: The quality control of biopharmaceuticals relies on a variety of analytical techniques, including high-performance liquid chromatography (HPLC), capillary electrophoresis (CE), and mass spectrometry (MS). This step involves comprehensive monitoring of the drug's purity, potency, stability and degradation products.

③Stability study: Stability study is a crucial step in CMC, as it affects the validity period and storage conditions of drugs. The CMC team collects stability data of drugs under different environmental conditions through long-term and accelerated stability tests to ensure the safety and efficacy of drugs during their shelf life.

④Technology transfer and scale-up: As drugs enter the later stages of clinical trials or are ready for market launch, the production scale needs to increase significantly, which poses higher requirements for the CMC team. Technology transfer is a key step in successfully scaling up laboratory-scale processes to industrial production scale. The CMC team needs to ensure that the quality of the drug after scale-up production is consistent with that during small-scale production.

⑤Regulatory filing: The preparation and submission of CMC documents is a crucial step in the drug registration filing process. The CMC team needs to prepare detailed documents detailing the chemical composition, manufacturing process and quality control procedures of the drug, and submit them to the regulatory authorities to obtain marketing approval for the drug.